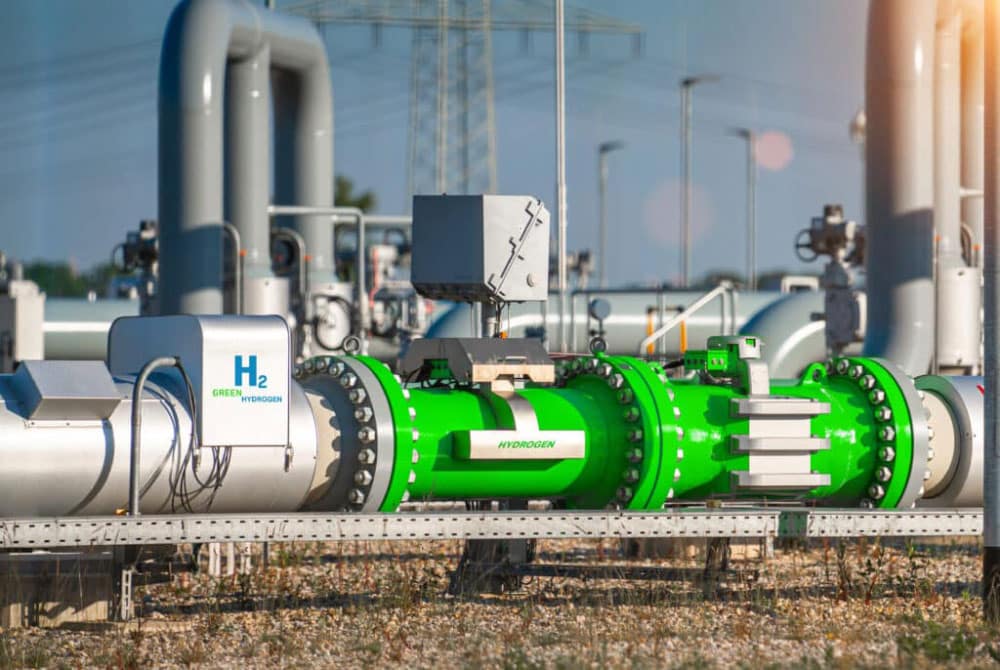

Tata Steel Trials Injecting Hydrogen Gas into Blast Furnace to Cut Carbon Emissions

India’s steel giant, Tata Steel, recently announced it had successful injected hydrogen into one of its blast furnaces. Many tout it as the world’s first such experiment by a steelmaker on so vast a scale. The goal of such a process is to potentially reduce carbon dioxide emissions by replacing up to 20% of the coke used in steel making with the gas. Given the immense implications such a breakthrough might have, steel news outlets were quick to cover the story.

The carbon in coke pulls oxygen away from iron ore, leaving behind pure iron. Hydrogen does the same, but without any greenhouse gas emissions. As per a statement issued by the Tata Steel, the experiment will provide valuable insights into operating blast furnaces with greener fuel injectant. If such efforts continue to be successful, it would be a huge step toward reducing fossil fuel consumption and subsequent CO2 emissions from the blast furnace.

MetalMiner Insights provides in-depth price forcasts and easy-to-follow should-cost models for numerous steel types and forms. Request a free consult.

How Large an Impact the Development Will Have

According to Debashish Bhattacharjee in recent steel news, Vice-President (Technology and RandD), Tata Steel, the experiment generated “enormous amounts of data.” The experiment used only a small quantity of hydrogen; about 6 kg per ton of hot metal for four days. Nonetheless, the Indian steel sector continues to hail the move as “a significant development” for steel making worldwide. Indeed, the industry has invested billions of dollars in building huge blast furnaces to make steel. However, these furnaces use mostly low-grade ores, which are predominant in India. These low grade metals are more harmful to the environment. Therefore, any inclusion of hydrogen is likely to reduce carbon emissions significantly.

Still, introducing hydrogen to the process remains challenging. This is mainly due to the external energy required and changes to the reactions inside the furnace.

Get weekly updates on steel news and much more with MetalMiner’s free weekly newsletter. Click here.

Steel News Outlets See the Experiment as a Huge Step Forward

According to Hindu Business Line, before this experiment, only two other hydrogen injection projects were reported by steel news outlets. The first was the 2015 Japanese Course50 project. This involved the indirect injection of hydrogen in the form of coke oven gas. The second was a 2021 experiment at ThyssenKrupp in Germany, where technicians injected 0.5 kg of hydrogen per ton of hot metal for several hours. The report clearly states that neither of these projects compares in scale or duration to Tata Steel’s experiment.

Tata Steel has been at the forefront of the “clean” steel movement. A few months ago, Tata Steel Nederland signed contracts with three companies: McDermott, Danieli, and Hatch. The firm stated that these businesses were to help them with further technical preparations for the hydrogen route. All three companies posses expertise that will help Tata Steel shape and deliver its hydrogen-based steel manufacturing.

The overall project is led by the Tata Steel’s internal project and sustainability team. These men and women will work in close support with the main delivery partners. Meanwhile, McDermott is responsible for providing construction input and supporting Tata through technical project management. Danieli is responsible for the engineering design for the plant and technology that delivers the Direct Reduced Iron (DRI), which is the first step in the iron-making process. Hatch is the technology licensor of the electric furnaces (REF). These melt the DRI and help to further reduce the oxygen content, thereby improving the final steel quality.

MetalMiner’s AI vastly improves your organization’s chance of making steel purchases which generate the most ROI. Read why.

Tata Will Continue to Explore New Green Manufacturing Options

Tata Steel representatives claim they want to transfer to green steel manufacturing in a clean environment as fast as possible. According to Hans van den Berg, CEO of Tata Steel Nederland, the company plans to achieve this transition primarily via the hydrogen route. Through this process, Tata would replace blast furnaces with modern clean steel-making technology, which uses hydrogen or gas instead of coal.

According to a steel news report from The Times of India, Tata Steel said it would require a huge quantum of hydrogen in the coming years. Rajiv Mangal, VP of Safety, Health, and Sustainability, stated in the report that the company continues to work “towards achieving net zero by 2045.” He also stated that the company is investigating multiple methods of achieving this apart from using hydrogen as fuel mix. Mangal added that there would be a requirement of 0.2-0.3 MT of hydrogen by 2030, and that one ton of crude steel produces around 2.5 ton of carbon using the latest available technology.

Experts say the recent experiment represents a significant step forward in reducing carbon emissions in steel making. The experiment generated a large amount of data, which Tata and its partners can use to facilitate further R&D.

While hydrogen has the potential to replace coke in steel making, the transition will not be a simple. The sector’s reliance on blast furnaces and the challenges associated with introducing hydrogen mean it may be easier to use the gas in electric arc furnaces, which require high-grade ores.

MetalMiner’s steel purchasing customers have saved millions of dollars by following MetalMiner’s industrial buying strategies. Take a look at MetalMiner’s track record.

Leave a Reply